Product advantages

Based on the independent research and development of Dawang ventilation PMSM (Permanent Magnet Synchronous Motor)The new HVLs super large energy-saving fan based on the principle of permanent magnet synchronization has professional and unique large fan blades and motors, which push out a large amount of quasi natural air circulation air flow, effectively solving the problems of hot and humid space, air stratification, peculiar smell, dust and so on.

-

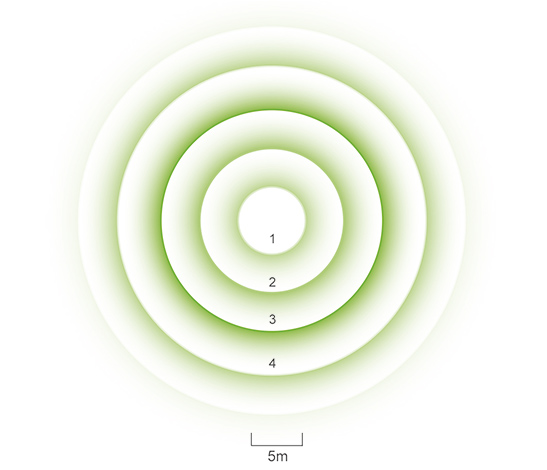

15072m³/min air quantity

15072m³/min air quantity8m super large diameter, 2400 ㎡ effective range, dispelling heat, humidity, smoke and peculiar smell

-

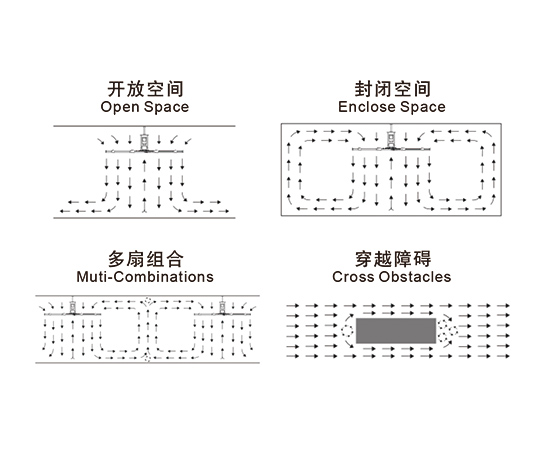

Omnidirectional dead angle free stereo cycle

Omnidirectional dead angle free stereo cycleAccelerate air circulation and effectively eliminate temperature stratification

-

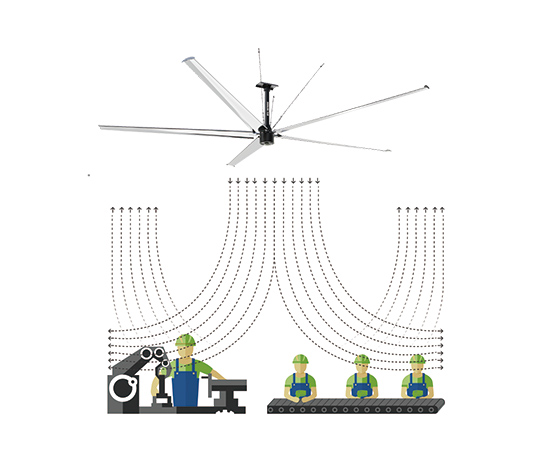

Comfortable and natural cooling

Comfortable and natural coolingSimulate the natural wind of level 2-3, the human body feels comfortable, the sweat evaporates rapidly, and the body feels cool by 5-8 ° C

-

Super mute

Super mute38dB ultra low volume to solve the problem of noise

-

More intelligent

More intelligentApp control, real-time monitoring of operation, active technical support, preventive maintenance strategy

-

More energy saving

More energy savingEnergy consumption per hour ≤ 1.2 kwh, reaching the standard of high efficiency and energy saving

-

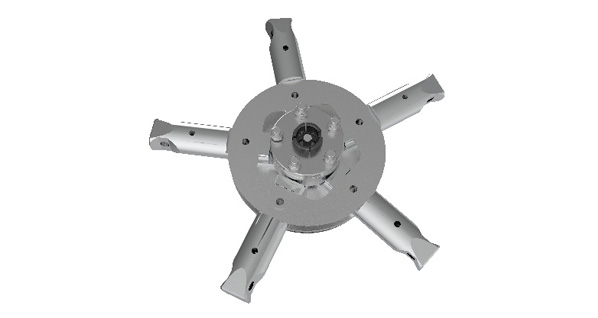

Patented blade

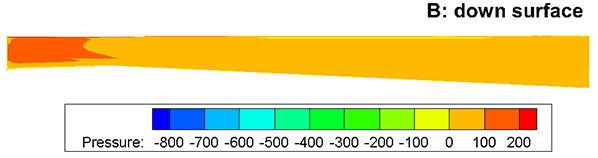

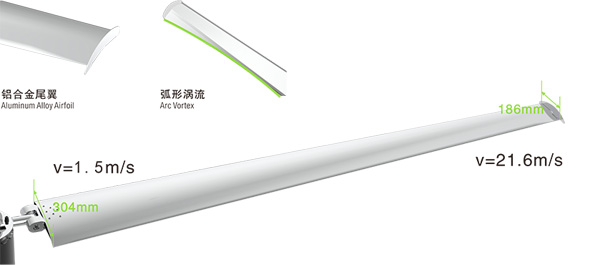

Fan airflow componentsA.Blade design - streamlined variable section

Applying the theory of equal chord length of aerodynamics and the principle of relative linear velocity, the blade root to blade tip gradually narrows (304-186mm) and thins (43mm-21mm), the force is more balanced, the air supply is more uniform, and there is no cavity in the center.

B.Blade material - aviation industry plate

It adopts 5052h32 high-grade 1.5mm aviation grade aluminum alloy motherboard, which is formed by precision numerical control, with higher strength and flexibility to ensure no fracture.

C.Blade weight - lighter and safer

Each blade is only 6.7 kg (7.3 m in diameter, excluding buffer parts). The number of blades is small, the weight is light, the motor load is reduced, the service life is prolonged, and it is safe and energy-saving.

-

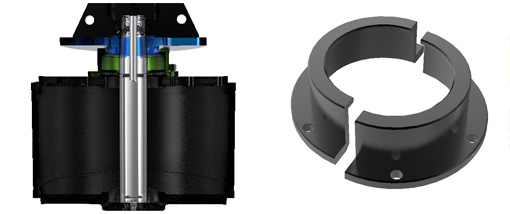

Buffer device

Fan efficiency assemblyA.Damping rubber

EPDM high-strength rubber buffer is set in the blade buffer chamber to effectively absorb the stress and airflow vibration from the blade, reduce the motor load, prolong the service life and make the operation more silent.

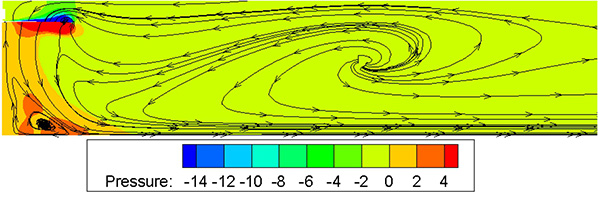

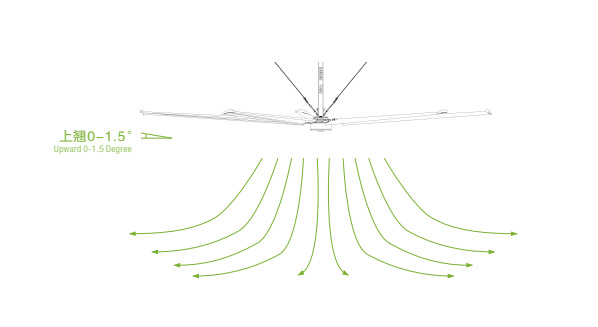

B.Upturned 0-1.5 °

The buffer cavity is equipped with a precisely calculated limit slot. When the fan is running, under the action of air flow, the buffer is freely adjusted in the limit slot of the cavity to realize the natural upward warping of the blade tip at 0-1.5 °, eliminate the reverse force generated during the operation of the fan, form a conical air flow, and realize that there is no cavity in the center and the coverage area is larger.

-

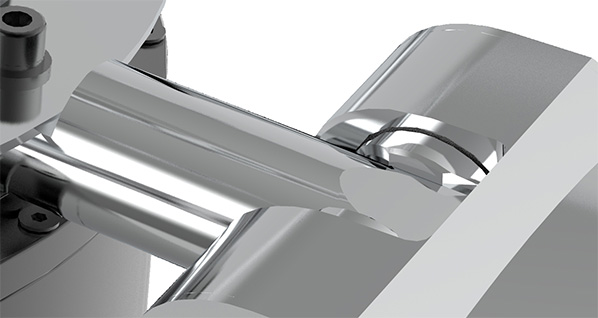

Tenon joint

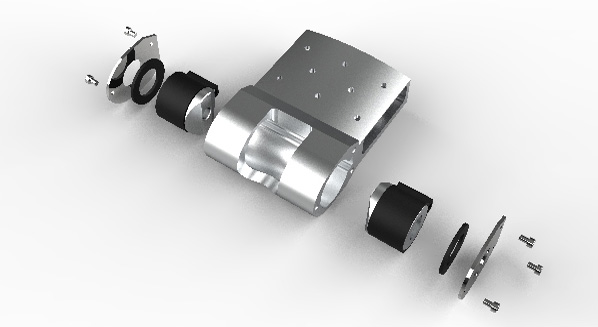

Fan safety coreA.Connection between blade and petiole

Tenon and mortise connection: the "concave" section of the blade handle forms a joint bite with the "convex" section of the buffer, so as to eliminate the outward centrifugal force of the blade during the operation of the fan and the shear force during the start and stop of the fan; The transverse screw is fastened in the same direction as the running track of the fan, free from right angle shear force, so as to ensure that the blade is not broken and fundamentally eliminate the potential safety hazard of secondary injury.

B.Connection between blade handle and hub

The connection between the blade handle and the wheel hub forms a whole between the blade handle and the wheel hub / motor through the mutual bite of the stepped concave convex section. The overall structure is used to bear the centrifugal force during the operation of the fan, and all fasteners are not stressed.

C.Connection between motor and wheel disc

Anti falling ring (asynchronous motor): connect the five blade handles into a whole and form a sleeve hanging with the lower wall of the frame to prevent the wheel hub from falling as a whole;

Anti falling disc (synchronous motor): the "concave" section of the flange and the "convex" section of the anti falling ring are engaged and hooked with each other under the action of gravity to ensure the reliable connection between the motor flange and the motor.